The only manufacturing app you’ll need

Features & Integrations

Fully Integrate Your Operations

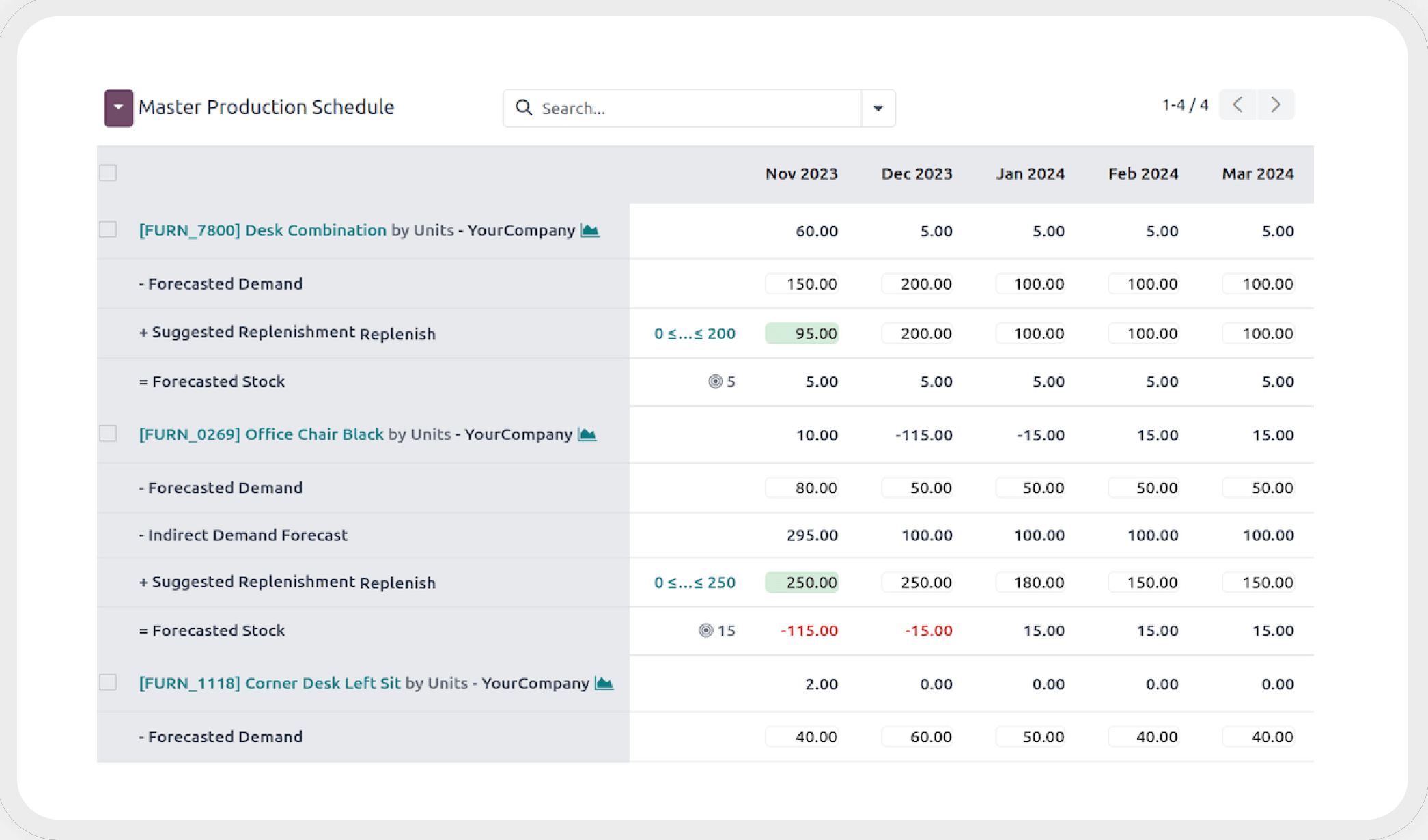

Optimised Inventory

Get just-in-time replenishment propositions and choose how to fulfil parts.

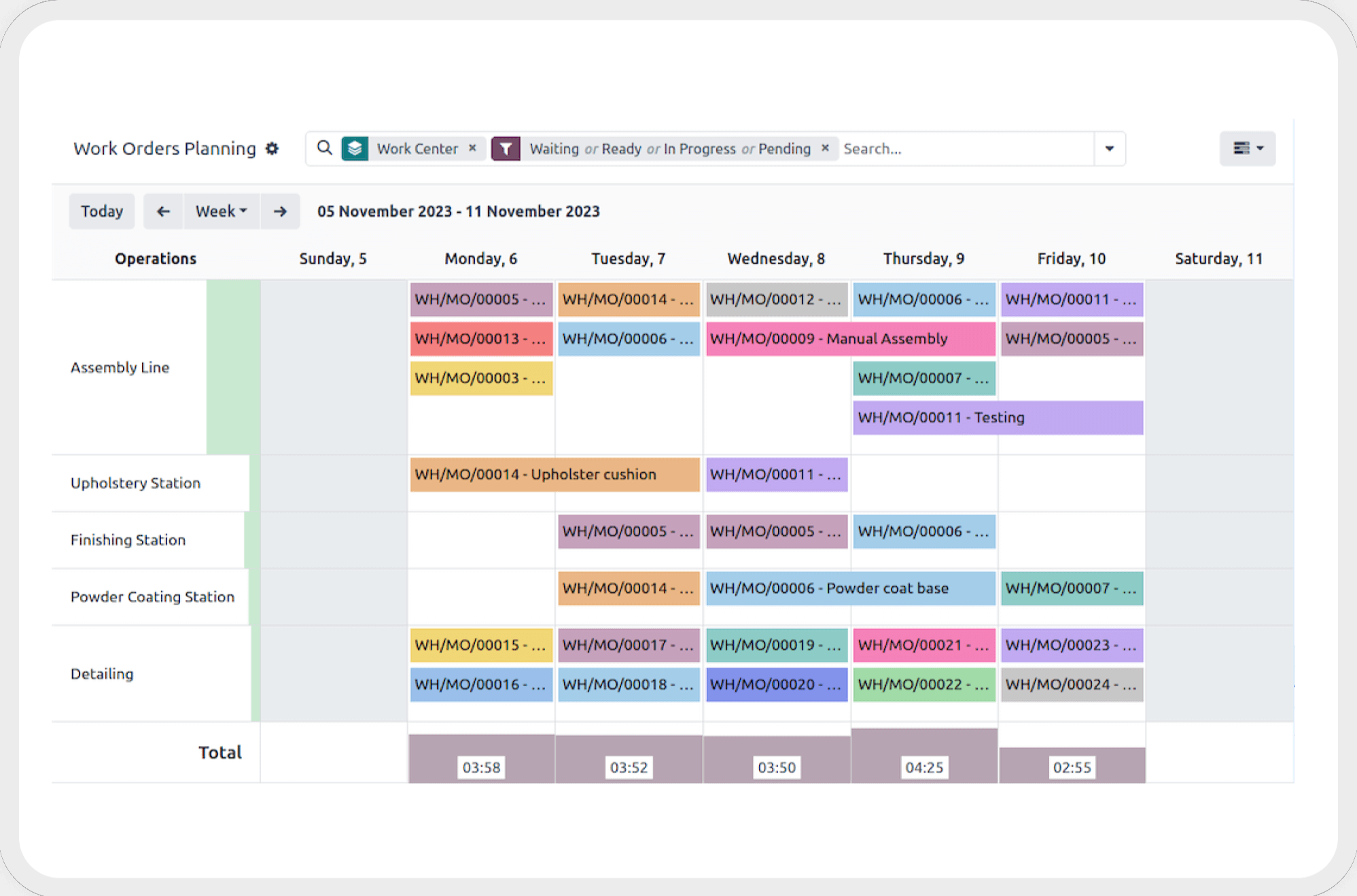

Manufacturing Reinvented

Get a clear view on your whole planning and easily reschedule manufacturing.

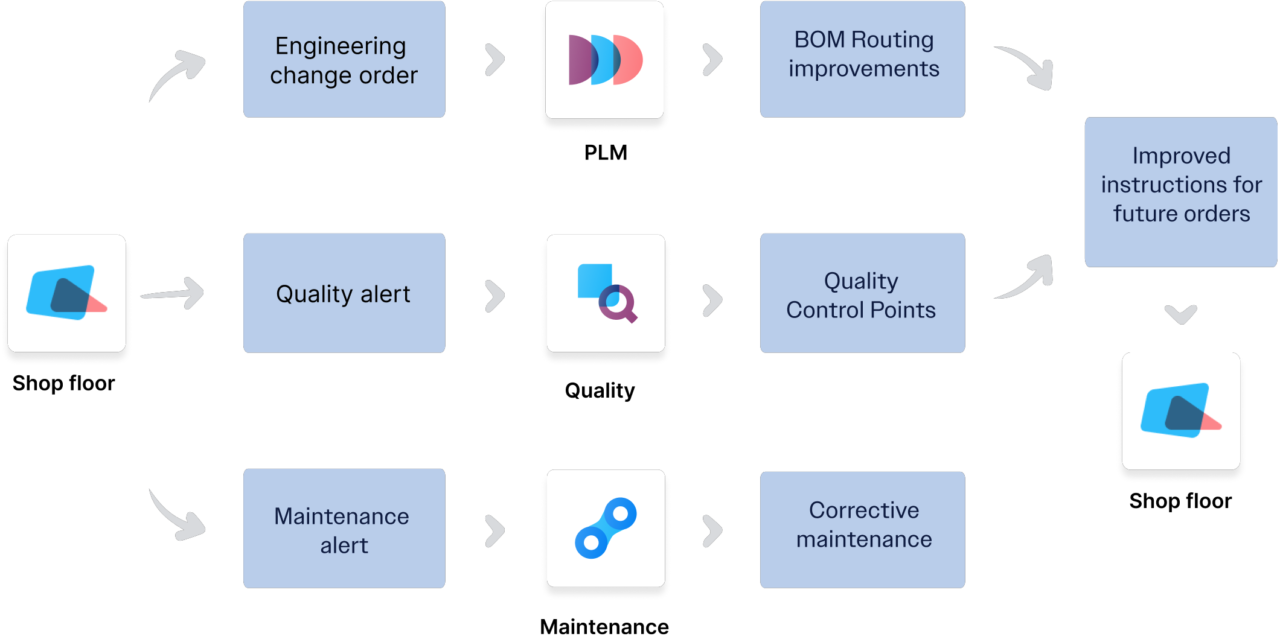

A Fresh Approach To A Long Standing Challenge

workforceX Helps You Win By:

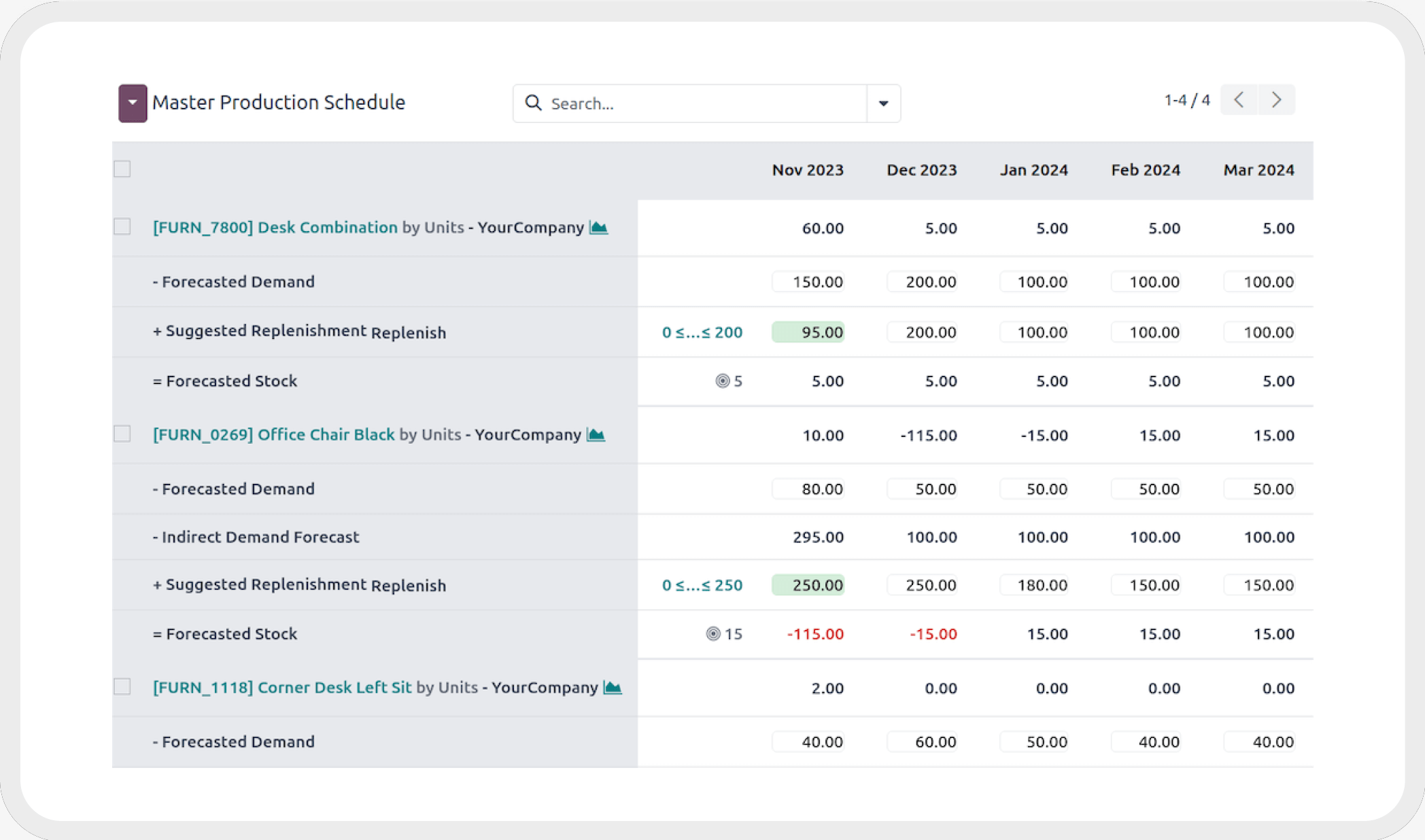

The MPS is perfect for your S&OP meeting, to align objectives of sales people and the manufacturing department.

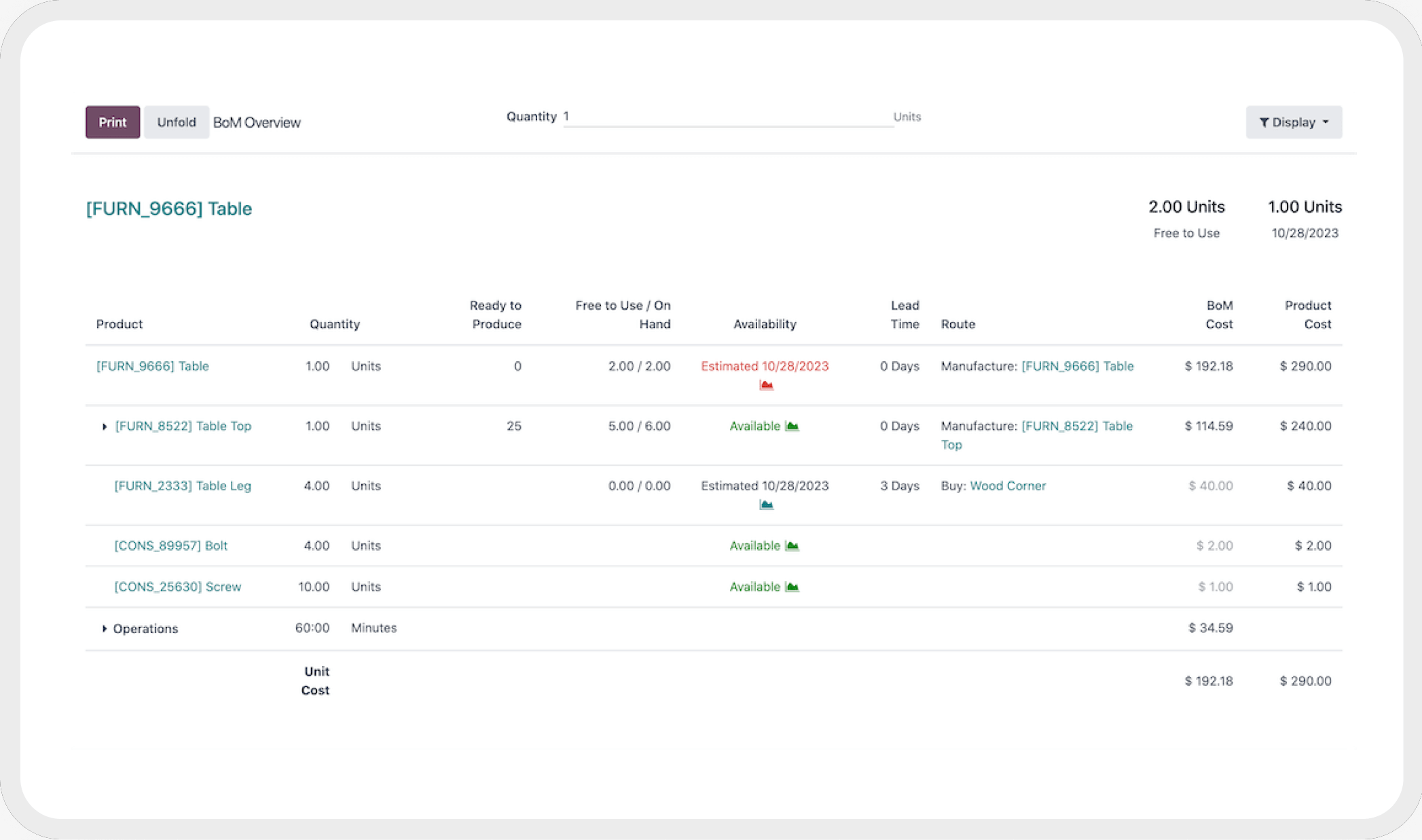

Simulate manufacturing orders with real-time capacity planning, components availability, and cost control.

Track components, or manufacture in batches (lots) or serial numbers. Get a clear traceability of all operations in just a click.

Connect barcode printers, automate quality measures, or setup your machine from the shop floor app, using the IoT box.

Barcodes, Out of the box

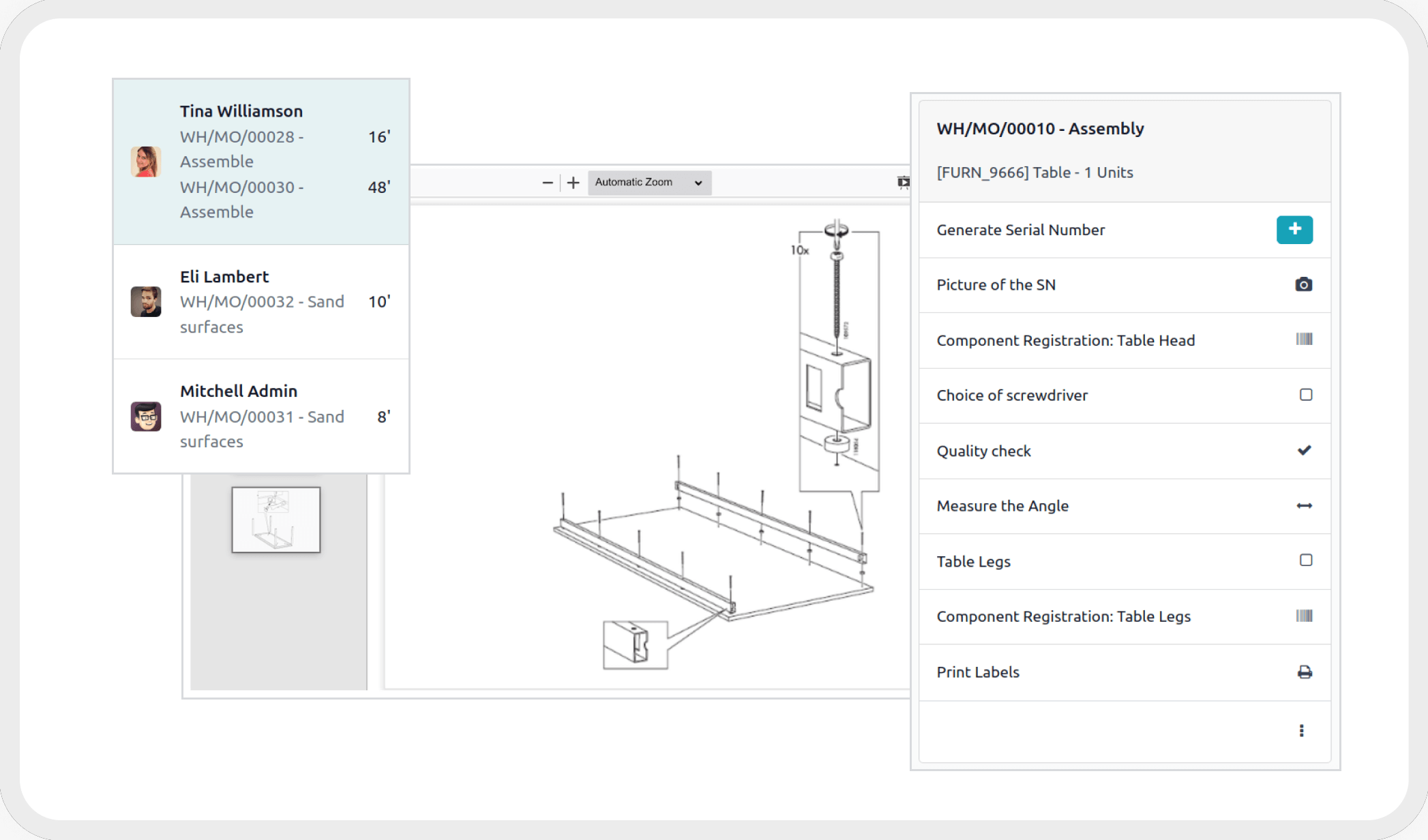

Use to process orders, accelerate operations, and reduce input errors. Works right out of the box, blasing fast, and with no latency. The Shop Floor app helps streamline your manufacturing line. Through the tablet-optimised dashboard, you can organise workers, workcenters, worksheets, quality tests, and much more.

Efficiency boosting tools for more convenience.

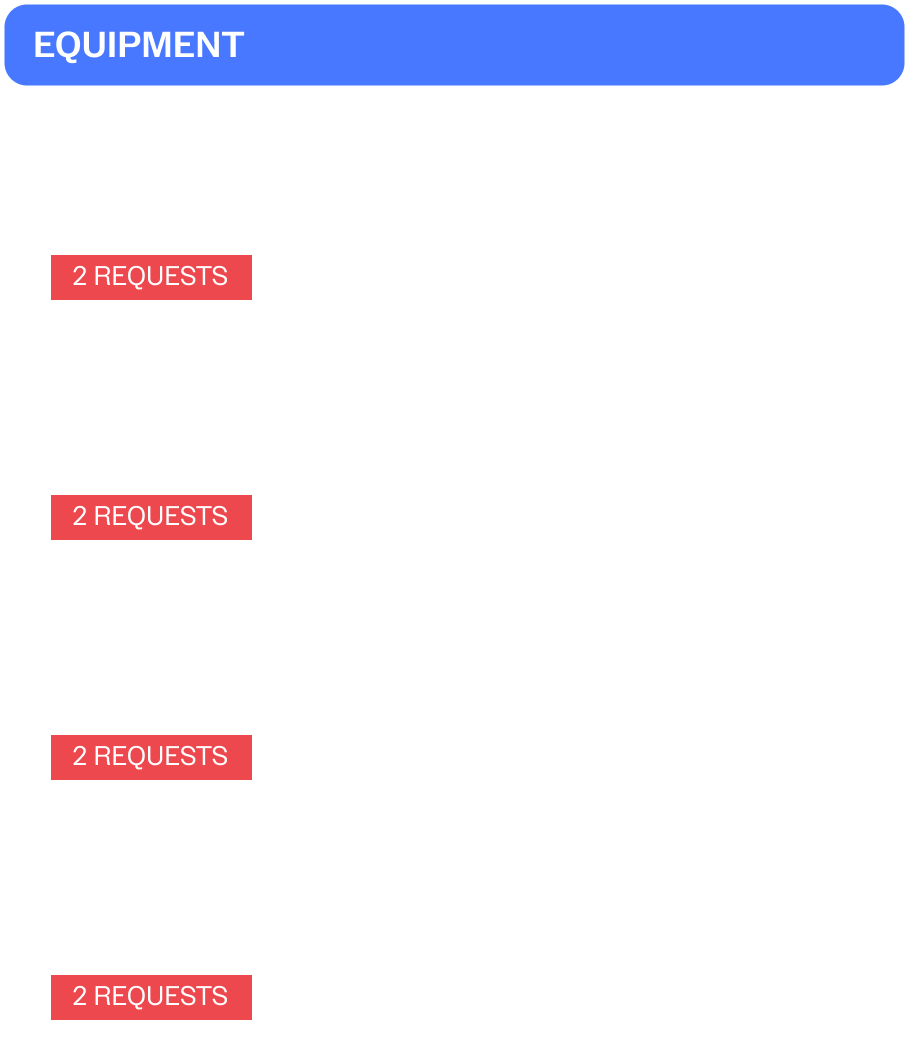

Organise Your Maintenance Requests

With great Kanban and Calendar views, you can effortlessly monitor the status of maintenance requests through the kanban view. Utilise the maintenance calendar for effective organisation and planning of activities. Your team will appreciate the user-friendly, drag-and drop interface for efficiently managing maintenance requests.

Manage all aspects of your leads in a single place.

Increase Overall Equipment Effectiveness

The manufacturing department has the capability to initiate maintenance requests directly from their work center control panel. As your maintenance team takes action, relevant personnel receive real-time updates. Enhanced communication minimises downtime and boosts manufacturing efficiency.

When ideas and information flow smoothly, quality is raised to the next level.

Your Partner In The APQP Journey

Establish quality control plans to initiate quality checks at designated inventory operations (e.g., receiving and final inspection) or during manufacturing operations (such as in-process inspections). Configure inspections for in-process, final, and receiving phases based on your defined quality control plans. Efficiently manage and monitor production part approval process (PPAP) submissions, and set up your statistical process control (SPC) as needed.

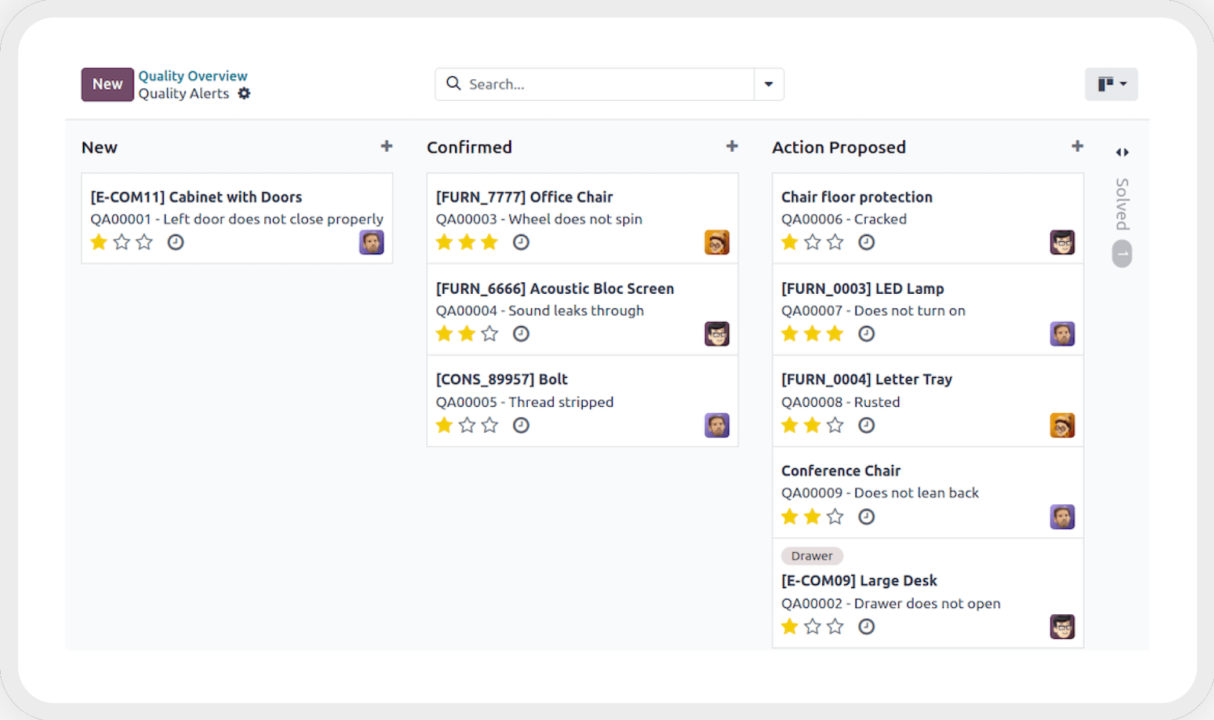

Manage Quality Alerts

Experience the convenience of managing your quality alerts in Odoo’s user-friendly kanban interface. Easily track progress by simply dragging and dropping alerts, and use visual indicators to prioritise critical issues. Efficiently categorise quality alerts by utilising tags, and set up rules to automate alerts or actions.